Viscous Coupler info.

superhatch

Moderator

superhatch

Moderator

Starting a discussion for info specifically about how VC's work, what ours is like, and possibilities of repar/replacement/upgrades.

MJH part: 40300-SH9-000 Drw#005 Qty:001 SHAFT ASSY., PROPELLER (NO.2) May Have Been Discontinued 948.33

http://www.angelfire.com/mech/civciwagon/rt4wd.html

Syncro.org (VW site)

How stuff works

Autozine.org

MJH part: 40300-SH9-000 Drw#005 Qty:001 SHAFT ASSY., PROPELLER (NO.2) May Have Been Discontinued 948.33

http://www.angelfire.com/mech/civciwagon/rt4wd.html

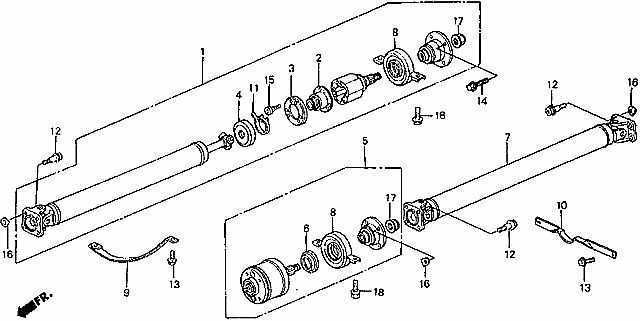

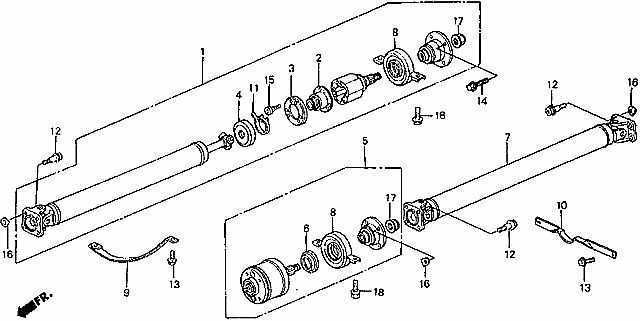

This is all straight from the 89 civic service manual.

Viscous Coupling

The viscous coupling unit is located on the front end of the No.2 propeller shaft. It consists of a housing that is connected to the No.1 propeller shaft by a tripod joint. Inside the houning are 79 plates, which have 0.2 mm (0.008 in.) of clearance between one another, surrounded by silicon oil. The 40 housing plates are engaged with the splines in the housing and the 39 hub plates are splined to the shaft. The plates have holes in them to aid in heat dissipation. The viscous coupling unit also contains approximately 10 % air to allow for the thermal expansion of the silicon oil.

Whenever there is any difference in the speed of rotation between the No.1 and No.2 propeller shafts, such as when the front wheels lose traction, there is friction between the housing plates (drive side) and the hub plates (driven side) .This friction is caused by the resistance of the plates sliding against the silicon oil. This resistance between the plates and the silicon oil is what begins to transmit torque from the housing plates to the hub plates and eventually to the rear wheels. This transmission of torque is proportionate to the difference in the speed of rotation of the wheels.

As the difference in propeller shaft speed continues, the temperature of the silicon oil keeps rising. Due to thermal expansion, the pressure inside the viscous coupling unit is also increasing as the temperature rises.

When the pressure becomes high enough, the housing plates begin to contact the hub plates and the engine torque to the rear wheels increases rapidly, as noted in the diagram below. To reduce plate wear, there are spacer rings to limit plate to plate contact.

Syncro.org (VW site)

When the front and rear wheels turn at different RPMs (at a rate greater than 6%), the shear force raises the temperature and viscosity of the silicon liquid inside the VC. The silicon becomes solid like and engages plates inside the VC with the result that power is transmitted from the center drive shaft (the engine) to the front differential (the front wheels).When the front and rear wheels begin to rotate at relatively the same RPMs again, the liquid deactivates," becomes less viscous and more liquid like, and as a result the front wheels/diff. disengage, and the van is powered again only or primarily by rear wheel drive.

How stuff works

Under normal conditions, both sets of plates and the viscous fluid spin at the same speed. When one set of wheels tries to spin faster, perhaps because it is slipping, the set of plates corresponding to those wheels spins faster than the other. The viscous fluid, stuck between the plates, tries to catch up with the faster disks, dragging the slower disks along. This transfers more torque to the slower moving wheels -- the wheels that are not slipping.

When a car is turning, the difference in speed between the wheels is not as large as when one wheel is slipping. The faster the plates are spinning relative to each other, the more torque the viscous coupling transfers. The coupling does not interfere with turns because the amount of torque transferred during a turn is so small. However, this also highlights a disadvantage of the viscous coupling: No torque transfer will occur until a wheel actually starts slipping.

A simple experiment with an egg will help explain the behavior of the viscous coupling. If you set an egg on the kitchen table, the shell and the yolk are both stationary. If you suddenly spin the egg, the shell will be moving at a faster speed than the yolk for a second, but the yolk will quickly catch up. To prove that the yolk is spinning, once you have the egg spinning quickly stop it and then let go -- the egg will start to spin again (unless it is hard boiled). In this experiment, we used the friction between the shell and the yolk to apply force to the yolk, speeding it up. When we stopped the shell, that friction -- between the still-moving yolk and the shell -- applied force to the shell, causing it to speed up. In a viscous coupling, the force is applied between the fluid and the sets of plates in the same way as between the yolk and the shell.

Autozine.org

Note that Viscous-Coupling LSD is a speed-sensing device: under no-slip condition, no torque will be sent to another axle. Whenever slip occurs, theoretically up to 100% torque can be sent to any axle, depending on the traction difference between front and rear axle. Therefore it is a part-time 4WD.

Being a part-time 4WD, it does not have the neutral steering of a permanent 4WD can obtain. For cars based on rear-wheel drive models, such as Porsche 911 Carrera 4, this is not a real problem - as normally the car runs like a RWD car thus is capable to deliver the desirable throttle oversteer . However, for other front-wheel drive-based cars like VW Golf Syncro and Volvo 850 AWD, the part-time 4WD can do nothing to correct their understeering manner. This is the first disadvantage.

The next problem is the delay before the 4WD get into effective. Since viscous liquid is not a fixed medium (unlike gear), it takes time and speed difference to be effective. The function between speed difference and torque transfer is an exponential function - that means in the early stage of slip, torque transfer remains near zero.

To cure this problem, most manufacturer varies the final drive ratio such that introduce a slightly speed difference even in normal condition. As a result, the car actually runs with 95:5 torque split between front and rear. This shorten the delay time. However, it is still impossible to match the pure mechanical Torsen LSD.

It might be less effective than Torsen system, but it is certainly the cheapest, so we can find it in many mass production 4WD cars.

Comments

I was looking on Majestic Honda for one of these the other day for fun, looks like it may be discontinued. The service manual tells you not to service it, just to leave it alone.

I'm assuming you're talking about the VC? If so, could we get a scan, or pic of it?

I'm not sure I agree with your conclusion. If, as you say, the rear wheels turn 99.3% the speed of the front wheels based on the drivetrain's gearing, then it seems that there is a slight preload of just under 1%.

It seems to me that only a perfectly matched front/rear wheel speed would result in zero preload. Is it your contention that less than 1% preload is, for all intents and purposes, essentially a 'zero preload?'

As for pre-load. My understanding is that the fronts need to be spinning faster than the rears in order for the VC to engage. If that's the condition to induce the VC wouldn't the rear wheels spinning slower be a pre-load? The VC locks when there is a difference in speed of the plates. In common practice this is because the fronts are spinning. If we slow down the rear plates by 0.7% wouldn't the fronts already be turning 0.7% faster? Ex. The threshold of lock is 5.0% difference in speed. If the rear plates are running at -0.7% the front only needs to achieve 4.3% change to create a 5% difference.

Thoughts?

Of course, I am partly operating on the assumption that Jaker's math is correct. And it may be possible that a .7% speed differential is insignificant in this particular circumstance. It would be interesting to hear from a Honda engineer on the topic.

I suspect that disengaging the rear drive shaft via the disconnect lever on the transmission would result in a slight increase in fuel economy; though it might not be enough to notice from one fill-up to the next unless the driver were superhumanly consistent in both driving routes and driving style from one tank fill to the next.

I thought the 84-87 had push button 4WD and it wasn't automatic?

Also, remember that torque transmission is variable based on difference in rotational speeds, torque is transmitted even below the 5% threshold, just not full torque. If a 5% difference in rotation causes full lock, then a .7% difference is more than 10% of the amount required for full lock. I would think that would be sufficient to generate a preload.

Of course, I've been wrong before.

http://stecouplers.com/recharge/modules ... x.php?id=9

They claim to "recharge" VCs. Pictures of numerous models.

Thanks for the response and ideas...

Phil in Alaska

To make a long story short, when you try and engage 4WD and it won't go in, this is basically what's happening All you need to do is rock the car slightly back and forth, and it should drop right in.

Take care, Phil in Alaska

Interested in their reply.

Glad you picked up the ball. I'd been thinking about contacting them, but I don't need one (yet), so motivation was lacking.

http://stecouplers.com/recharge/modules ... x.php?id=9

last night and asked about rebuilding. To my surprise, I received a reply this morning.

"Good Morning Craig: By my info. your Honda has a transfer case without a viscous coupler. I base this on the fact we have never seen one or been asked for one, and I have no cores for it so if you do have one I would need yours to even see if this is something we could reman. Other than that this is a dealer part. Sorry I don`t have better news for you but if I do find info on this one I will e-mail you

Dave H. STE Couplers "

I am in the market for a non-functional VC to send to them. Anybody?

Are there spider/differential gears "between" the FWD portion of the transmission and the transfer-case portion? If there are, then creating a one-piece driveshaft or somehow locking the VC together will not cause a failure when driving on pavement. The spider gears will allow the rear wheels to turn at different speeds than the front. This is how most normal 4x4s work that have "full-time 4wd". It will likely decrease MPG, however.