drums done right with tricks ....

ok guys this is my crx ... same principle but i am doing a serious over haul on these puppies it started making a crazy noise it turns out that some metal from the rear housing was being minced into tiny bits cause it rusted to peices .....

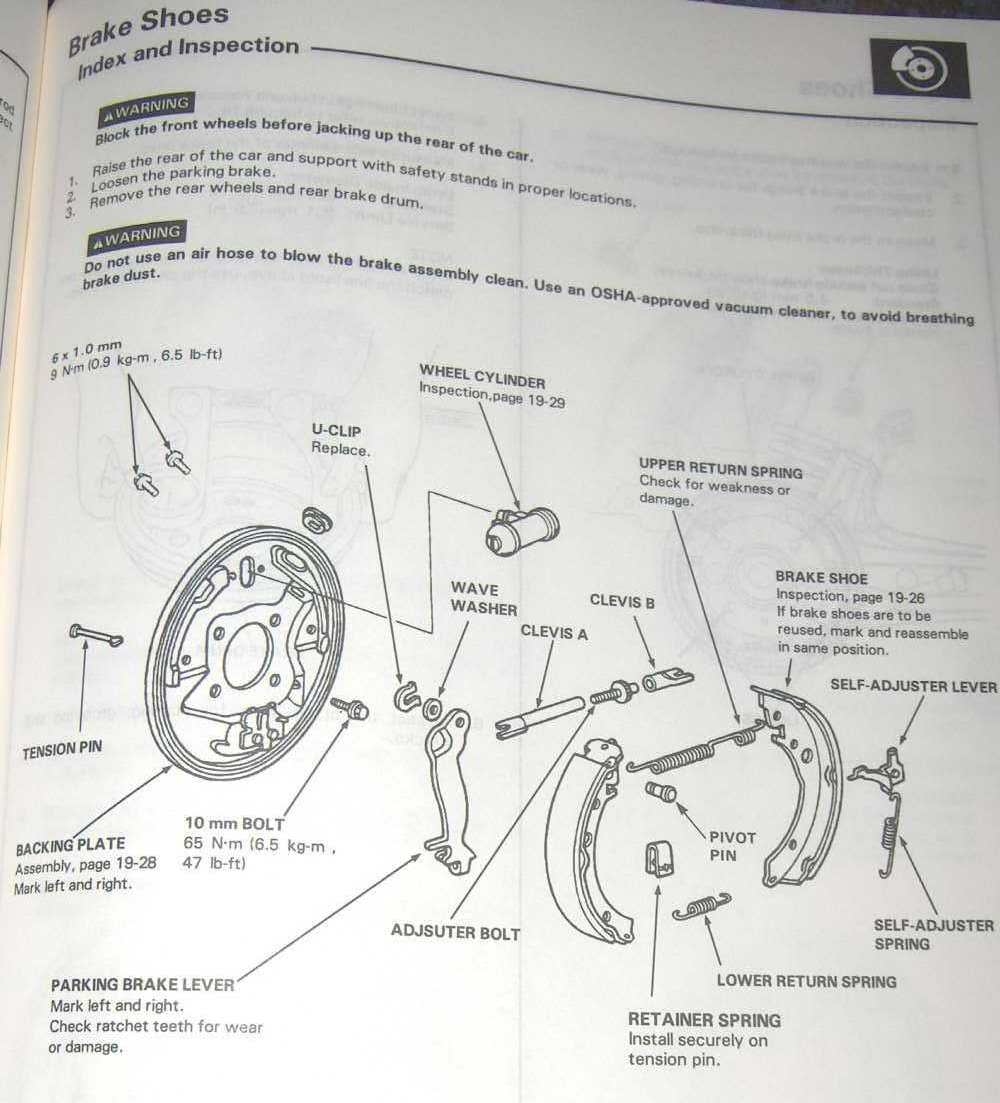

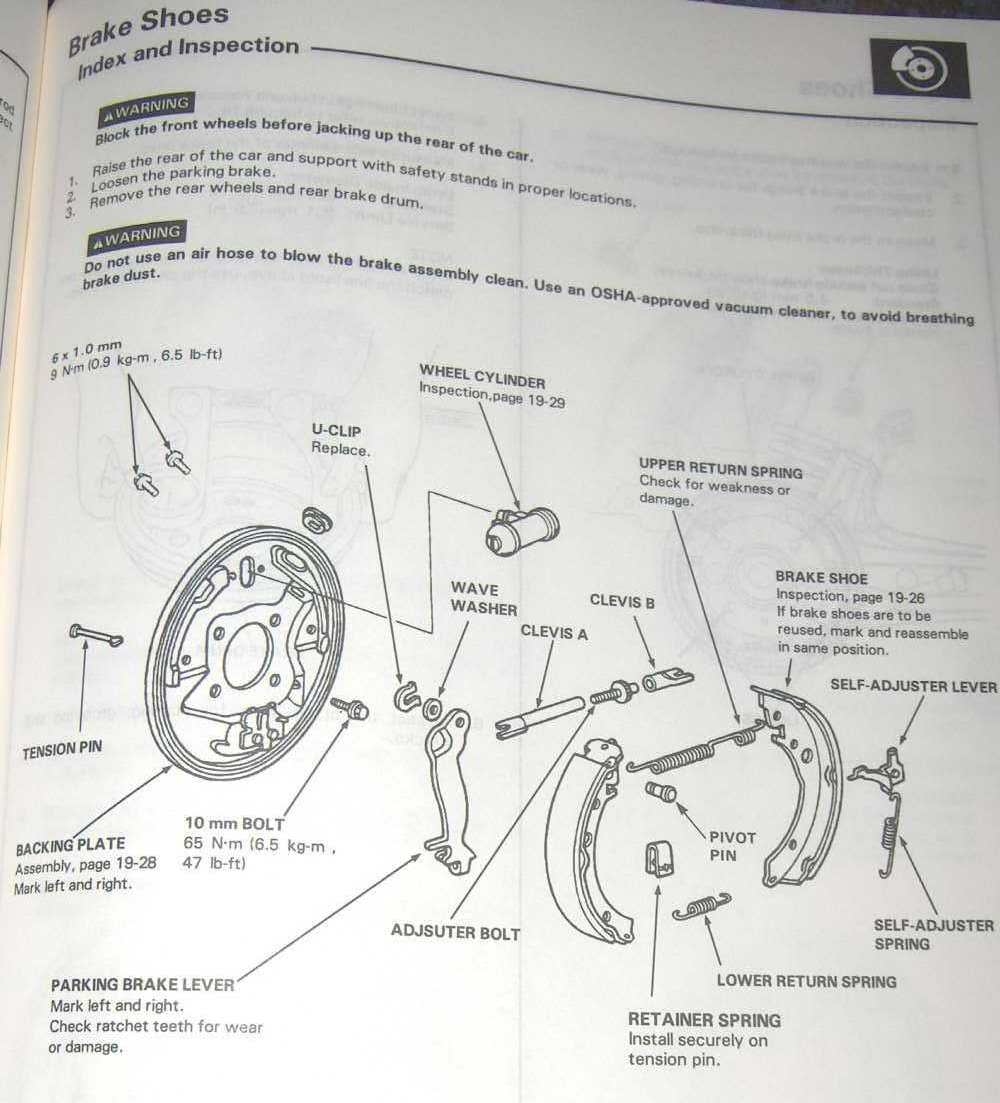

here is a schematic from a civic wagon book so this isnt from the crx ...

anyway here is the start note the crazy brakes dust ....

now take your time and remove stuff without breaking it .... i cleaned everything throughly and it is an extremely dirty job ... when your done this is what you need to save in that other pic you saw the old drum and pads all junk at this point .... this is what you wanna see when you are ready for the next step

ok now for the trick i learned from old hot rod guys on a show that if you drill drums next to the wear surface they vent the heat and gas and some dust ... i just did 2 tiny holes cause this is a beater but i figure it will help a tiny bit you can go crazy and drill your heart out on both sides of the wear surface too you may wanna experiment with some grove in the surface or maybe a drilling pattern just try to place them on equal sides so it isnt way of balance it is not a big deal but make it close you may wanna mark it all out first i just eyed it up with the wheel stud holes...

take special care drilling this cast metal i am a machinest and let me tell you cast is a bitch breaking bits is very easy use light pressure while drilling ...

look close at the outer edgs there are 2 holes .... at like 3 and 9 o clock

now for the second trick

rusty anything sucks so i tried my hand at costing these with POR15

this stuff is no joke i have seen it withstand some serious shit and it is like kryptonite for rust ... anyway i washed them in soap and water you must remove grease if you do this and with this product it actually like rust so if you leave them in the rain for a day thats better than greasy new ones .... if you look close you can see the vent hole on the outside too ...

now put it all back together and use lenty of neverseize or goood grease on everything !!!!! i use it on the wheel studs and the surface where your wheel sits so it wont rust on

once again RUST IS THE FUCKING DEVIL !!!!!!!

well its 1 am and thats all the farther i am i am waiting for the rotors to dry, well they are hard all ready but i wanna be sure before i clamp them on

i cleaned the insides of my hx wheels and painted the h in the center for kicks ...

i will update with some final pics this only cost me 76 bucks with the good rotors and lifetime pads so this is a easy weekend project that will make your car nicer safer and you never need to look at those yucky rust ball drums and it needs done on any old car ....

here is a schematic from a civic wagon book so this isnt from the crx ...

anyway here is the start note the crazy brakes dust ....

now take your time and remove stuff without breaking it .... i cleaned everything throughly and it is an extremely dirty job ... when your done this is what you need to save in that other pic you saw the old drum and pads all junk at this point .... this is what you wanna see when you are ready for the next step

ok now for the trick i learned from old hot rod guys on a show that if you drill drums next to the wear surface they vent the heat and gas and some dust ... i just did 2 tiny holes cause this is a beater but i figure it will help a tiny bit you can go crazy and drill your heart out on both sides of the wear surface too you may wanna experiment with some grove in the surface or maybe a drilling pattern just try to place them on equal sides so it isnt way of balance it is not a big deal but make it close you may wanna mark it all out first i just eyed it up with the wheel stud holes...

take special care drilling this cast metal i am a machinest and let me tell you cast is a bitch breaking bits is very easy use light pressure while drilling ...

look close at the outer edgs there are 2 holes .... at like 3 and 9 o clock

now for the second trick

rusty anything sucks so i tried my hand at costing these with POR15

this stuff is no joke i have seen it withstand some serious shit and it is like kryptonite for rust ... anyway i washed them in soap and water you must remove grease if you do this and with this product it actually like rust so if you leave them in the rain for a day thats better than greasy new ones .... if you look close you can see the vent hole on the outside too ...

now put it all back together and use lenty of neverseize or goood grease on everything !!!!! i use it on the wheel studs and the surface where your wheel sits so it wont rust on

once again RUST IS THE FUCKING DEVIL !!!!!!!

well its 1 am and thats all the farther i am i am waiting for the rotors to dry, well they are hard all ready but i wanna be sure before i clamp them on

i cleaned the insides of my hx wheels and painted the h in the center for kicks ...

i will update with some final pics this only cost me 76 bucks with the good rotors and lifetime pads so this is a easy weekend project that will make your car nicer safer and you never need to look at those yucky rust ball drums and it needs done on any old car ....

Comments

they have a few colors here ill just check the sites

http://www.por15store.com/page/por15/PROD/Topcoats/HN

that shows the colors

but i think i have like the original formula ... they have many products includeing a manifold paint that is great

because i didnt adjust the thing out enough oh yea i took the time to do a rear bleed on ther lines im gonna do the fronts sometime soon

I have and have already used por 15 on my wagon parts & the stuff is serious as hell. If you dip a bracket in it, rust will never come back

AT ALL!!!!!!!

I have considered coating all the back surfaces of my doors and my hatch with it

http://www.eastwoodco.com/jump.jsp?item ... SubCat=852