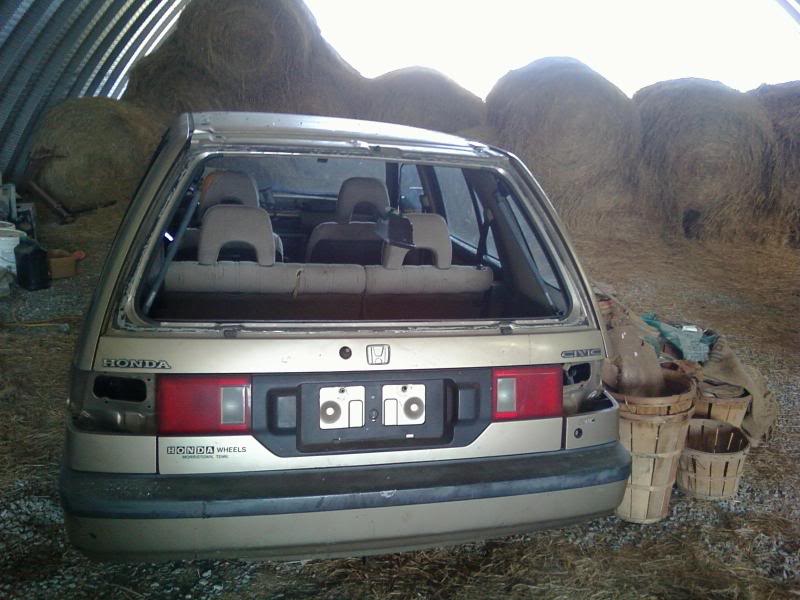

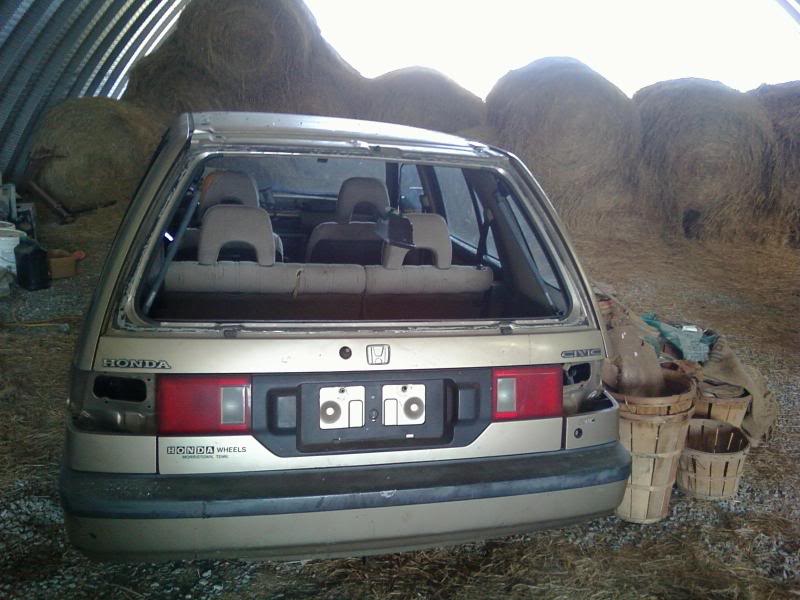

my 88 EE4 project... warning: slow progress

this is post copied from D-series.org... it was posted on 05-25-2009, and yes the pics are terrible... i dont care

on to the pixz of my super fugged up wagon

the good:

on to the pixz of my super fugged up wagon

the good:

Comments

starting to remove the mounts to pull the engine.

out she comes:

empty bay:

as it sits in my garage now, waiting for the tranny to be removed, then the engine is junk minus the oil pan which i plan to remove and fix.

next weekend im planning on getting the new driver side front fender and doors, passenger side front door, and rear window.

at the same time ill be gutting the rest of the engine bay to prepare for paint/wire tuck and gutting the interior

well im going to steal jaker's idea and put a solid drive shaft in with a modified LSD in the rear end... but im leaving the front wheel drive active as well, powered by a boosted z6 (225ish hp)... and lots more

TurboTeg was the 1st to do the 1 piece driveshaft thing (no viscous coupler), but I think I was the 1st to fit an LSD into the rear diff.

i see... well i will be jacking both of your ideas (if you dont mind?)... and i will PM you pretty soon with a couple questions on the specifics (again, if you dont mind?)

ok... which LSD did you use? D series or B series? ive heard both...

and what exactly did you drill out to make it fit?

also, what type of axles did you have to end up using? i know they were custom but is there a stock axle that will work?

The bolt holes that the bolts to hold the ring gear onto the diff were the ones I had to open up. Since the ring gear has threaded holes, and they're normal right hand thread, the threaded holes in the diff (left hand thread) have to be opened up to let the bolts pass through. The diff is hardened steel. I don't think you'll have much luck drilling them out. I used a grinding stone in my Dremel to do 2 of them. That took about 2 hours and the 2nd hole ended up a little biger than I wanted. The other 8 holes were done by a machine shop. It wasn't very expensive, and was so much more accurate that I could have done it.

You need to use FWD inner joints. The same ones that you would use if the diff was mounted in a FWD car like 92-95 Civic. The inner joints are different lengths on FWD. The inner joints of the rear axles on the RT4WD Wagon are the same length. The seats in the diff for the circlip that holds the axle in are not the same distance into the diff. I never investigated the possibility of using FWD inner joints with RT4WD rear axles. I knew I was going to want much beafier axles. You won't be able to use FWD axles in the back. The length needed is right in between the left and right FWD axle lengths. I don't know of any other OEM axle that will fit.

The shimming of the diff will also need to be adjusted. You need the lash between the ring and pinion to be just right. The OBX diff has slightly different width than the regular RT4WD rear diff. I had an transmission and diff shop do the shimming for me, as I was not comfortable in my skills to do it myself, and I know this area is going to be critical in my build. It was expensive, but I'm more comfortable with the rear diff now. I brought various shims with me (I took all the shims out of the 4 diffs I have here, and bought some shims from the transfer case for the 1st gen CRV - very close to the same dimensions). In the end, the shop ended up using some shims that they had there.

i believe ive got acess to all the machinery needed to open up the holes (full machine shop at my job)... and ive got some co workers that might be able to help me with the shimming... if not then ill take it to a tranny shop like you.

how hard is it to change the ends out on OEM axles? i might go that route

opening them up...

i wont be getting the doors/fender/glass this weekend as i got laid off yesterday so i cant justify spending money on such things right now

but i will be gutting the engine bay & Interior this weekend, and if I have another Job landed by next week ill pick the body parts up then

http://www.progressauto.com/products/sfID1/133/sfID2/34/sfID3/88/productID/486