Soldering References

greenteagod

Moderator

greenteagod

Moderator

I did a bit of searching around but didn't find anything definitive on here regarding soldering, so I'll post this regarding my foray from utter noob, to slightly better than noob.

My first soldering iron was a 15 watt pencil from Radio Shack. It did most of the things I needed to do, like modding playstations/dreamcasts, building video game controllers.

Then through work I was able to expense a Hakko 936.

I've had it for over a decade now and it's still kicking, so that tells you the longevity of them. At the time of this post though they're not selling the 936 any longer, but the FX888D is equivalent price and is a good iron in itself. (though it does look a bit play-skool in comparison)

*Update Youtubers EEVBlog and Arduinoversusevil both recommend the Hakko 888. If you're familiar with either of them, it's good to have their stamp on it.

If you plan on doing any soldering over the years I definitely recommend. You can change out the tip depending on what you're soldering and it covers a huge temperature range so you can dial it in just as needed. I know sometimes there's the want to just crank it all the way up, I still do that from time to time myself, but that can actually burn alloys out of the solder which leads to a weaker joint. That said, we're not working on rocket ships here, but if you can take the moment to do it right, why not.

So with regard to soldering technique, I highly recommend reviewing these videos. This guy is a NASA certified instructor and while the cameraman is a hack you get a good idea of what's going on and how to produce a very clean reliable solder joint. One thing that I really like about this technique is how two wires are soldered together. They do not twist them together depending on the spec. They tin both wires and then touch them side by side and solder them together as such. This allows for a good solid joint that if needed can be disassembled quickly. If you have your wires twisted and then solder, if you ever have to take that connection apart for any reason you're likely going to be cutting out the joint.

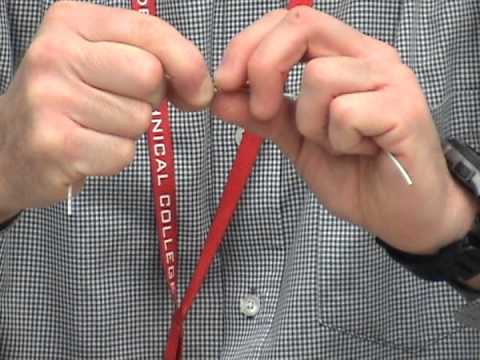

Before the videos, just a quick shot of a little helper tool that was made with some 12 gauge solid wire and a couple alligator clips. It acts as a third hand for holding two wires side by side if you're not doing the twist method. It also acts as a heat sink so the heat stays more isolated to where you're soldering instead of creeping up and melting back your insulation.

*EXPERT LEVEL* Soldering Tutorial #1 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #2 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #3 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #4 TTC Avionics

In the below one he does do the twist method and shows how to do it to achieve the best result, this is with thinner gauge wire though (22ga) so this method may not work for heavier gauge. It, like the other methods, involves tinning the wires fully before you connect them to each other.

*EXPERT LEVEL* Solder Splice Tutorial TTC Avionics

My first soldering iron was a 15 watt pencil from Radio Shack. It did most of the things I needed to do, like modding playstations/dreamcasts, building video game controllers.

Then through work I was able to expense a Hakko 936.

I've had it for over a decade now and it's still kicking, so that tells you the longevity of them. At the time of this post though they're not selling the 936 any longer, but the FX888D is equivalent price and is a good iron in itself. (though it does look a bit play-skool in comparison)

*Update Youtubers EEVBlog and Arduinoversusevil both recommend the Hakko 888. If you're familiar with either of them, it's good to have their stamp on it.

If you plan on doing any soldering over the years I definitely recommend. You can change out the tip depending on what you're soldering and it covers a huge temperature range so you can dial it in just as needed. I know sometimes there's the want to just crank it all the way up, I still do that from time to time myself, but that can actually burn alloys out of the solder which leads to a weaker joint. That said, we're not working on rocket ships here, but if you can take the moment to do it right, why not.

So with regard to soldering technique, I highly recommend reviewing these videos. This guy is a NASA certified instructor and while the cameraman is a hack you get a good idea of what's going on and how to produce a very clean reliable solder joint. One thing that I really like about this technique is how two wires are soldered together. They do not twist them together depending on the spec. They tin both wires and then touch them side by side and solder them together as such. This allows for a good solid joint that if needed can be disassembled quickly. If you have your wires twisted and then solder, if you ever have to take that connection apart for any reason you're likely going to be cutting out the joint.

Before the videos, just a quick shot of a little helper tool that was made with some 12 gauge solid wire and a couple alligator clips. It acts as a third hand for holding two wires side by side if you're not doing the twist method. It also acts as a heat sink so the heat stays more isolated to where you're soldering instead of creeping up and melting back your insulation.

*EXPERT LEVEL* Soldering Tutorial #1 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #2 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #3 TTC Avionics

*EXPERT LEVEL* Soldering Tutorial #4 TTC Avionics

In the below one he does do the twist method and shows how to do it to achieve the best result, this is with thinner gauge wire though (22ga) so this method may not work for heavier gauge. It, like the other methods, involves tinning the wires fully before you connect them to each other.

*EXPERT LEVEL* Solder Splice Tutorial TTC Avionics

Comments

My old hakko has been kicked around in a box, been in the dusty wood shop and it's still kicking. So if anyone is soldering with a little pencil welder from radio shack or the like, do yourself a favor, buy a decent soldering iron. It'll be the best $100 you've spent for anything like this.