Tool Review: kwik-lift Ramps.

greenteagod

Moderator

greenteagod

Moderator

Porting this over from my build thread, since I think it merits its own post. Also this is in no way a paid review. I think they're an amazing addition to a garage shop and if it suits your needs I'd definitely say get one, but no one is paying me to say that. They were purchased from kwik-lift.com and at the time of purchase I spent $1650 with tax and shipping. I had a second "center bridge" added on as well, it's the black crossmember you see spanning the ramps.

Apologies for the cluttered pics, when my garage is more sorted out I'll reshoot.

Assembly was fairly straight forward. There are 8 bolts total that whole the ramp halves together. This also allows you to adjust them to the desired length. I have them set at the shortest since I don't have a massive garage. Even at that they're still a bit over 13' long which is plenty enough for our wagons. I had some help getting the pieces out of the truck, since I didn't want to scrape everything up dragging the ramp parts across each other, but actual assembly was done by myself. Just making a point of that as I weigh about 135lbs and the weight on the ramps assembled is about 750lbs That's divided across 9 large parts and then some minor hardware. So while the parts might be a little awkward if you're assembling in a tight space, it's definitely doable.

I didn't take any pictures during assembly so this might appear a bit out of order. But what I did was have one ramp fully assembled, and the other I didn't have the ramp pinned in the front leg. I installed the jack tube, which you can see in the following picture. This was done with some 5 gallon bucket assistance just to have things propped up on while I slid it all together. Once the jack tube was in, then I was able to space them appropriately for the center bridges to set down into the grooves. They are very heavy duty and have some 90 degree angle welded to them which allows them to socket right into the grooves on the ramps.

Here's a closer picture of the rod that the ramps pivot on.

Now for actual usage. I need to snap a better picture of the approach ramps but you'll see them in a later picture. What we do though is pretty straight forward. You drive your car onto the ramps, and chock the wheels. I don't have my center bridges positioned yet, this was just test usage. You'd just want to get them positioned under any points you'd actually use to place jack stands. Then you use a bottle jack, to lift the car high enough to get the wheels off the ramps, place your stands, then pop the wheels off as needed.

With the car on the ramp then use the floor jack to lift up the entire rear of the ramps together, via that massive jack bar. Then lower the rear legs.

They are held securely in the up and down positions via a spring pin, which you can see here. Just put one hand on the leg, lift it slightly to take the tension off the pin, pull the pin and then the leg lowers smoothly. Once fully lowered the pin will pop back in once it's locked.

Then lower the ramps onto the rear legs, and you're good to go. You can see the small approach ramps below as well. Since the can be a bit slick with the fresh powdercoat, and if there's any moisture on the wheels, this can help get up that little gap without spinning tires. Also if you've lowered your wagon, or just have a generally low car, this little bit can help.

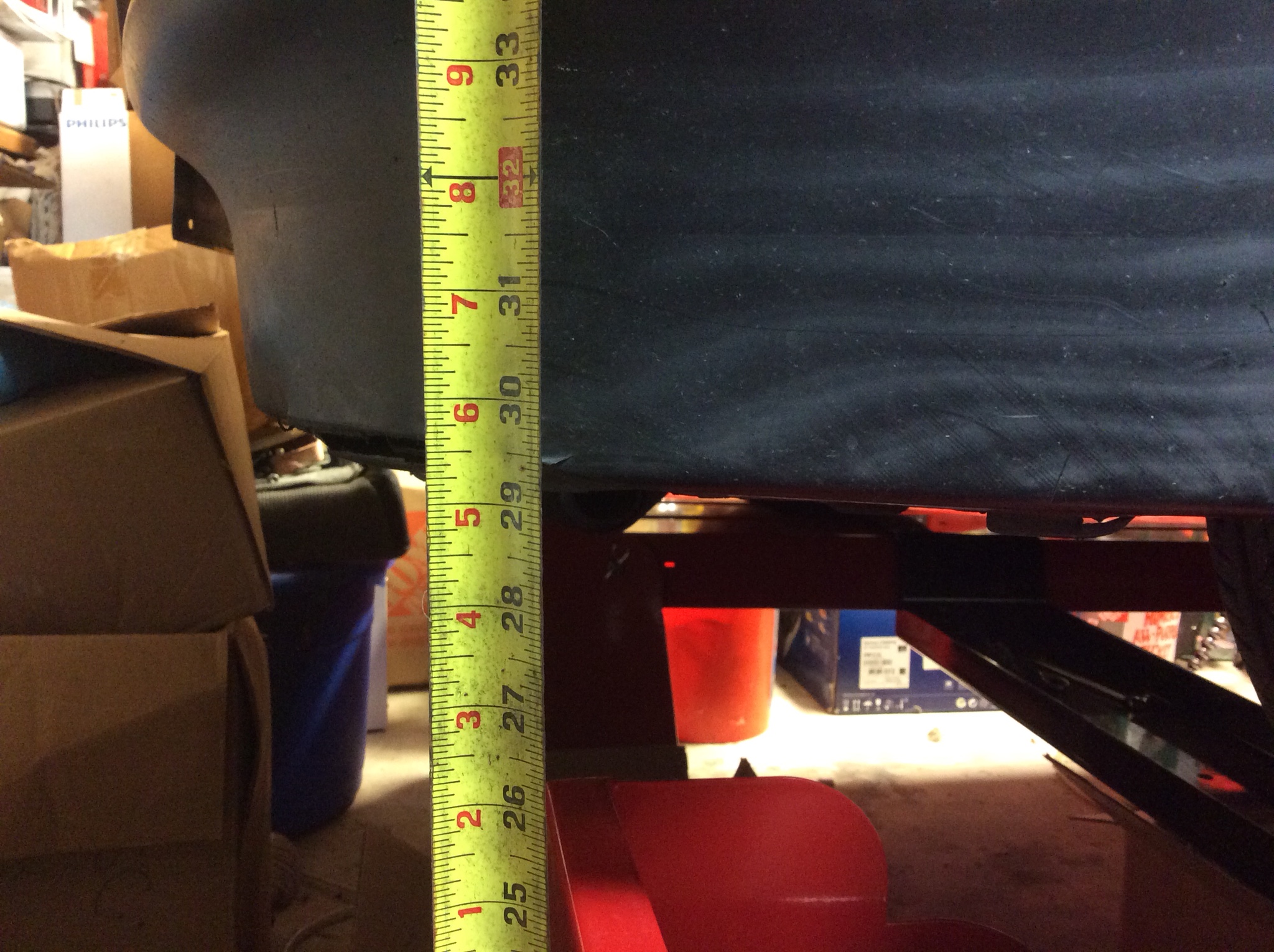

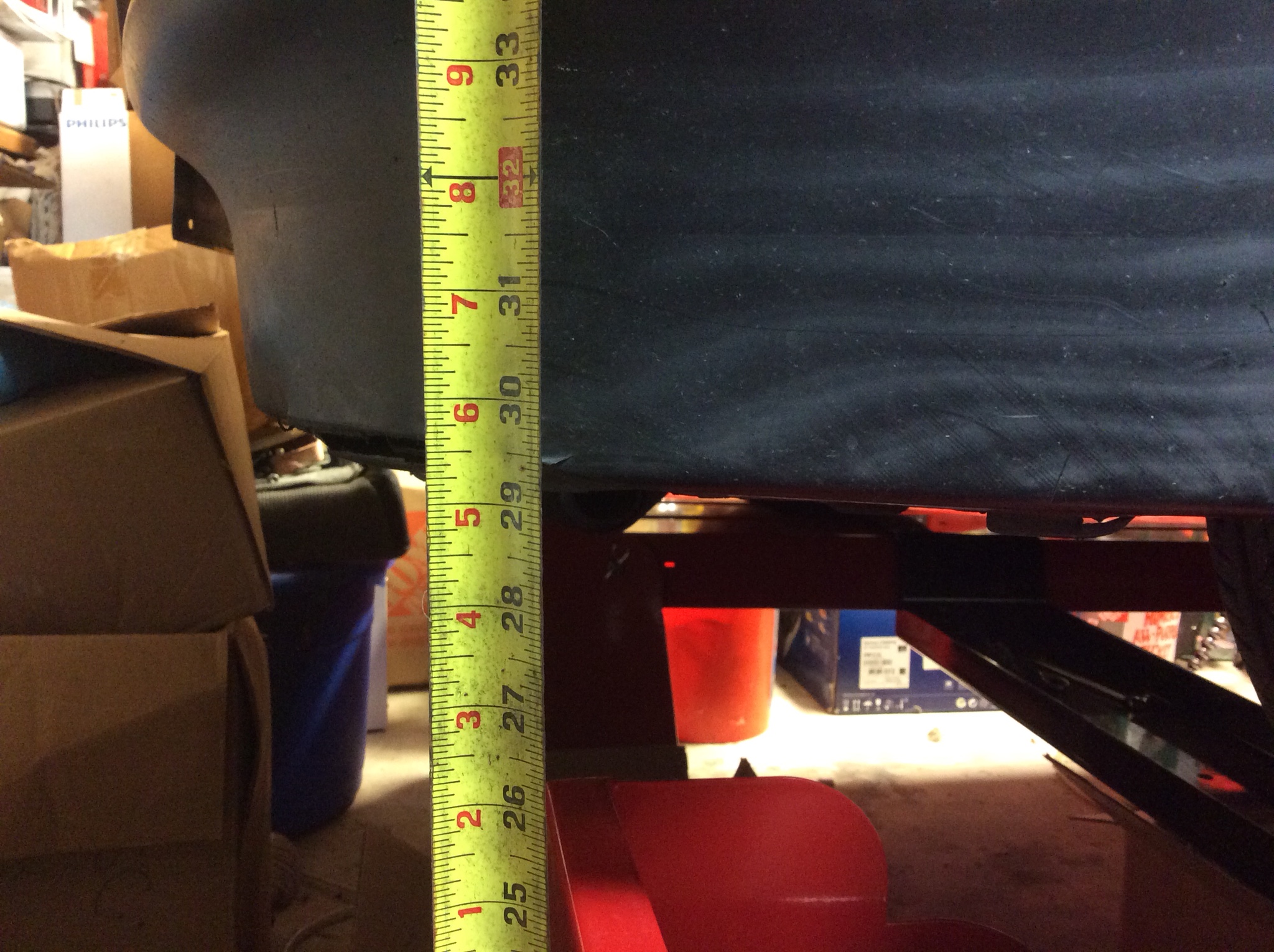

I don't have it all the way pulled forward so I could probably get an inch or so more height at the front since the ramps aren't totally level. But you can see that I have great clearance at the front bumper. And just a few inches less at the rear. Yeah it's not as great as if you have access to a full lift or a garage equipped for one, but hey for the garage mechanic this is pretty sweet.

Also you can see here I have a standard 8 foot heigh ceiling in the garage and this is the clearance I have from the top of the car to the garage door. No problem at all with it coming too close to it.

Another point to mention is the jack bar itself. With it being a tube, it's designed to rotate in the ramps. This allows you to have it in a "down" position while driving a car onto the ramps. It lays flat, below the height of the ramps. Then you just grab this bar and rotate the bar "Up" for getting the jack under there and lifting, or lowering the ramps.

One more shot underneath, I just love all that room to work with.

With the car up on the ramps, you're not crammed under there like you would be with just your regular rhino ramps. This puts nearly everything under there at arms length. When I was installing my traction bar it was pretty much hold the impact off to the side of me because I didn't have room to hold it in front. You'll know what I'm talking about when you're doing stuff blind or at awkward angles. Yeah you have enough room to get under there, but barely enough to work. Even with my small frame, getting under there with a roller basically put my nose against the oil pan. So it was mostly just wiggle on my back. Now I can easily maneuver under the entire vehicle on a creeper.

If you have any questions about this, feel free to ask and I'll do my best to answer them. If you're interested in the ramps themselves, head on over to kwik-lift.com

I went with the full blown package, but you can get the ramps as low as about $1000 + shipping if you're not wanting them powdercoated and don't need the center bridges.

Cheers

Apologies for the cluttered pics, when my garage is more sorted out I'll reshoot.

Assembly was fairly straight forward. There are 8 bolts total that whole the ramp halves together. This also allows you to adjust them to the desired length. I have them set at the shortest since I don't have a massive garage. Even at that they're still a bit over 13' long which is plenty enough for our wagons. I had some help getting the pieces out of the truck, since I didn't want to scrape everything up dragging the ramp parts across each other, but actual assembly was done by myself. Just making a point of that as I weigh about 135lbs and the weight on the ramps assembled is about 750lbs That's divided across 9 large parts and then some minor hardware. So while the parts might be a little awkward if you're assembling in a tight space, it's definitely doable.

I didn't take any pictures during assembly so this might appear a bit out of order. But what I did was have one ramp fully assembled, and the other I didn't have the ramp pinned in the front leg. I installed the jack tube, which you can see in the following picture. This was done with some 5 gallon bucket assistance just to have things propped up on while I slid it all together. Once the jack tube was in, then I was able to space them appropriately for the center bridges to set down into the grooves. They are very heavy duty and have some 90 degree angle welded to them which allows them to socket right into the grooves on the ramps.

Here's a closer picture of the rod that the ramps pivot on.

Now for actual usage. I need to snap a better picture of the approach ramps but you'll see them in a later picture. What we do though is pretty straight forward. You drive your car onto the ramps, and chock the wheels. I don't have my center bridges positioned yet, this was just test usage. You'd just want to get them positioned under any points you'd actually use to place jack stands. Then you use a bottle jack, to lift the car high enough to get the wheels off the ramps, place your stands, then pop the wheels off as needed.

With the car on the ramp then use the floor jack to lift up the entire rear of the ramps together, via that massive jack bar. Then lower the rear legs.

They are held securely in the up and down positions via a spring pin, which you can see here. Just put one hand on the leg, lift it slightly to take the tension off the pin, pull the pin and then the leg lowers smoothly. Once fully lowered the pin will pop back in once it's locked.

Then lower the ramps onto the rear legs, and you're good to go. You can see the small approach ramps below as well. Since the can be a bit slick with the fresh powdercoat, and if there's any moisture on the wheels, this can help get up that little gap without spinning tires. Also if you've lowered your wagon, or just have a generally low car, this little bit can help.

I don't have it all the way pulled forward so I could probably get an inch or so more height at the front since the ramps aren't totally level. But you can see that I have great clearance at the front bumper. And just a few inches less at the rear. Yeah it's not as great as if you have access to a full lift or a garage equipped for one, but hey for the garage mechanic this is pretty sweet.

Also you can see here I have a standard 8 foot heigh ceiling in the garage and this is the clearance I have from the top of the car to the garage door. No problem at all with it coming too close to it.

Another point to mention is the jack bar itself. With it being a tube, it's designed to rotate in the ramps. This allows you to have it in a "down" position while driving a car onto the ramps. It lays flat, below the height of the ramps. Then you just grab this bar and rotate the bar "Up" for getting the jack under there and lifting, or lowering the ramps.

One more shot underneath, I just love all that room to work with.

With the car up on the ramps, you're not crammed under there like you would be with just your regular rhino ramps. This puts nearly everything under there at arms length. When I was installing my traction bar it was pretty much hold the impact off to the side of me because I didn't have room to hold it in front. You'll know what I'm talking about when you're doing stuff blind or at awkward angles. Yeah you have enough room to get under there, but barely enough to work. Even with my small frame, getting under there with a roller basically put my nose against the oil pan. So it was mostly just wiggle on my back. Now I can easily maneuver under the entire vehicle on a creeper.

If you have any questions about this, feel free to ask and I'll do my best to answer them. If you're interested in the ramps themselves, head on over to kwik-lift.com

I went with the full blown package, but you can get the ramps as low as about $1000 + shipping if you're not wanting them powdercoated and don't need the center bridges.

Cheers

Comments

Definitely so. I also like it because it's portable in a sense. Excluding having to bolt them down to a slab that can take the stress, the posts on a two post lift are a beast to move. This thing I can break down into parts that weigh at most around 100 lbs. Set it up in a driveway somewhere reasonably flat etc etc... and get things rockin'

I'll try to get a measurement of the approach angle on these things, just for lowered car reference. And keep in mind since I have these dialed in the shortest the angle is gonna be the steepest. You could definitely shave off a few degrees by extending them out to the full 14'9 feet.

Oh and another thing I thought I'd mention, that might come across a little ironic on a site for Hondas, but they are made in the USA right up in Tulsa Oklahoma. I definitely have nothing against made in Japan stuff, otherwise I'd hope to be quickly ostracized here, but what I don't like seeing is a car perched above me and whatever bit of pot metal is holding it up says Made in China on it.

Also, a non issue for the wagons themselves, but anyone else owning these might want to put other vehicles up on it. At shortest length they're capable of 6000lbs and at fully extended it's about 5000lbs.