How to: Remove studs and broken studs (exhaust and intake)

Well I am sure some of you guys know how to do this little trick but this is for those that don't.

You will of course need access to a welder. I used my mig welder for this. Hopefully you have a friend with one or own one. Might save you a trip to some overpriced shop.

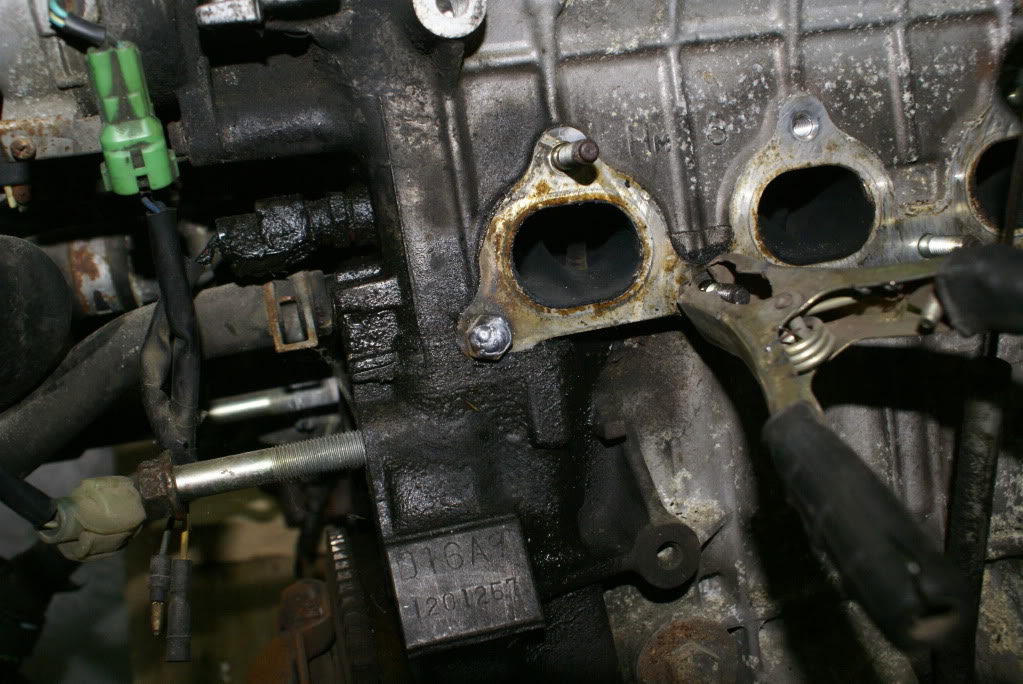

So when removed my exhaust manifold I had two studs break.

Nothing is ever easy so I wasn't going to take this to a shop to do so I grabbed the welder and filled the hole. The heat will probably definately help break it lose. The weld won't stick to the aluminum head. On this one I had enough weld metal on the outside to grab it with some vice grips. Oh yeah and remove the metal gasket or you will do like I did and weld it to the bolt :oops:

The second was a little harder to get out so grab yourself an old nut. Hold it with pliers, place it over the weld, and fill the hole up. Make sure you get a good weld deep in the nut.

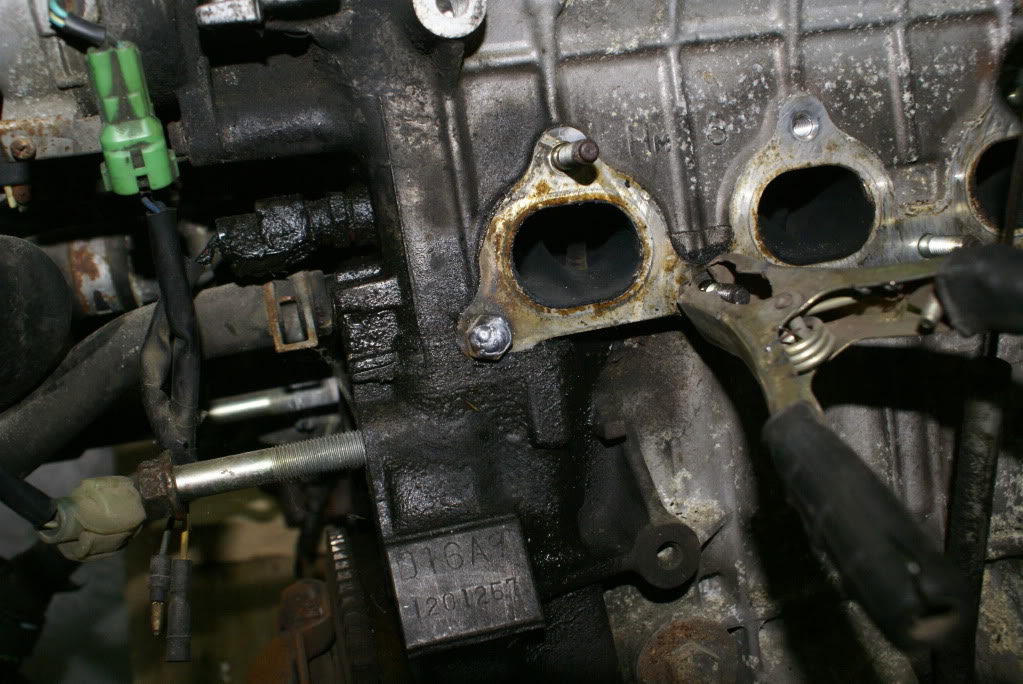

Now when I went to take my intake manifold off to get the ZCspeed adapter plate on there I couldn't get some of the studs off. Most of the time the two nuts on the stud locked down on each other works but these were pretty stubborn.

So again get you some nuts and thread them onto the stud that won't move. I have about 3-4 threads sticking out to get some good space to weld. This is what mine looked like after welding.

And here are removed studs.

You will of course need access to a welder. I used my mig welder for this. Hopefully you have a friend with one or own one. Might save you a trip to some overpriced shop.

So when removed my exhaust manifold I had two studs break.

Nothing is ever easy so I wasn't going to take this to a shop to do so I grabbed the welder and filled the hole. The heat will probably definately help break it lose. The weld won't stick to the aluminum head. On this one I had enough weld metal on the outside to grab it with some vice grips. Oh yeah and remove the metal gasket or you will do like I did and weld it to the bolt :oops:

The second was a little harder to get out so grab yourself an old nut. Hold it with pliers, place it over the weld, and fill the hole up. Make sure you get a good weld deep in the nut.

Now when I went to take my intake manifold off to get the ZCspeed adapter plate on there I couldn't get some of the studs off. Most of the time the two nuts on the stud locked down on each other works but these were pretty stubborn.

So again get you some nuts and thread them onto the stud that won't move. I have about 3-4 threads sticking out to get some good space to weld. This is what mine looked like after welding.

And here are removed studs.

Comments

For the broken studs, you can drill a hole in them and use a reverse bit tool to twist them out backwards. Most auto parts places have them for pretty cheap. The fun part is drilling the steel stud - doesn't drill very fast. he he

As you can see I tried that already and it did not work.

Also welding the broken stud was a lot faster than trying to drill into a head onto a broken bolt.

Update. Got the hole drilled out till I was able to pick out the metal from the treads. Ran a tap down the treads and breathed a sigh of relief.

How does the welder not ruin the treads when you fill I am just amazed at the welding idea. Is it a cable feed that fills the hole?

for the recessed one take your time- center punch it and drill it but start small then "step up" drill bit sizes. it took me some time but the end result were clean threads and head.